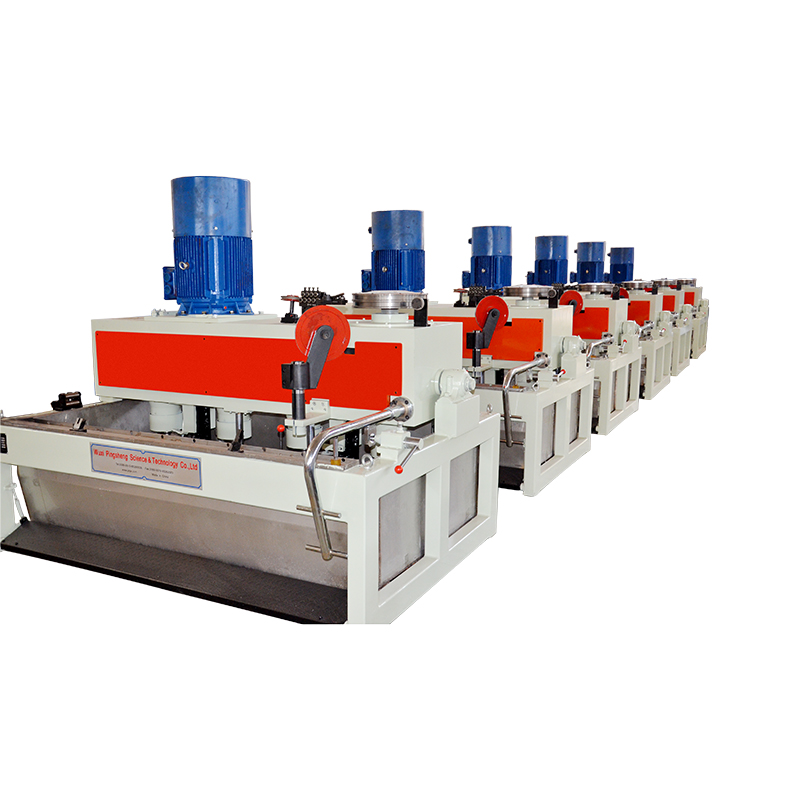

Turnover wet wire drawing machine is flip type for double side drawing. It has the function of compact structure, easy operation, space saving. It can achieve high total compression rate, low partial compression rate of multi-pass continuous drawing. There are good lubrication conditions, adapted to high-speed or higher speed drawing. Unwinding, drawing and I-beam bobbin rewinding are combined into one unit, and the rewound steel wires, whether they are finished products or semi-finished products, are of good quality and are flexible in use. The equipment adopts frequency conversion speed control, PLC control and constant tension, constant wire speed, fixed length meter counting and other automation functions to ensure the consistency of the winding tension and disc weight of the products. The equipment meets the technical requirements necessary for large-scale, continuous production.

It applies in the production of steel cord and hose steel wire, brass plated steel wire, galvanized steel wire rope, tape wire rope, aviation wire rope, stainless steel wire and etc.

EN

EN

English

English Español

Español Français

Français Português

Português عربى

عربى