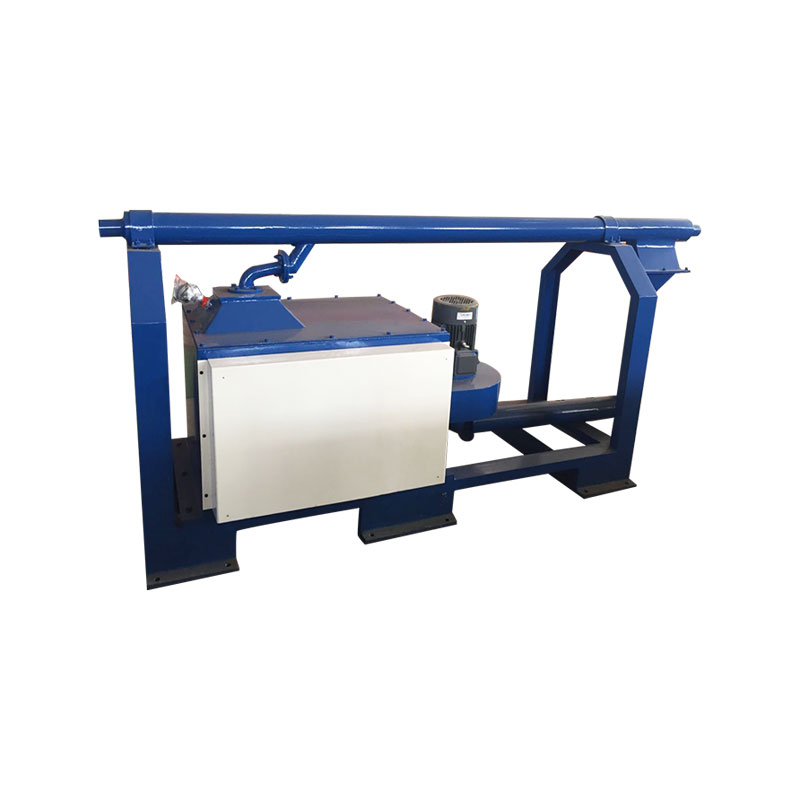

Metal Wire Surface Treatment Line: A Key Process for Improving Quality and Performance

In modern industrial manufacturing, metal wires (such as steel wire, copper wire, aluminum wire, etc.) are widely used in many fields such as construction, automobiles, electronics, and home appliances. However, untreated metal wires are susceptible to corrosion, wear, or oxidation, which reduces their service life and performance. In order to improve the durability, aesthetics, and functionality of metal wires, the Wire Surface Treatment Line came into being. This technology can not only significantly improve the surface properties of wires, but also meet the diverse needs of different industries for material performance.

This production line usually consists of multiple modules, including pretreatment equipment, surface treatment devices, drying furnaces, cooling systems, and quality inspection equipment to ensure that the entire production process is efficient and accurate.

Main processes for metal wire surface treatment

Cleaning and degreasing

Before surface treatment, oil, rust, and other impurities on the surface of the metal wire must be thoroughly removed. This step is usually completed using chemical cleaning agents or ultrasonic cleaning technology to ensure the effectiveness of subsequent treatment.

Plating treatment

Plating is one of the most common surface treatment methods. For example, zinc plating can enhance the corrosion resistance of wires, while nickel plating can improve hardness and oxidation resistance. These coatings are attached to the surface of wires through electrolysis or hot dipping processes to form a uniform and strong protective film.

Coating treatment

The coating process uses spraying, dipping or electrostatic spraying to cover the surface of the wire with a layer of organic or inorganic materials (such as polyester, epoxy resin). This treatment method not only prevents corrosion, but also gives the wire a specific color and texture, which is suitable for decorative purposes.

Heat treatment and passivation

Heat treatment can improve the mechanical properties of wires, while passivation generates a dense oxide film through chemical reactions, further improving its corrosion resistance. These two processes are often used in combination to achieve the best results.

Drawing and polishing

Drawing and polishing are indispensable steps for wires that require high precision and smooth surfaces. They can reduce the surface roughness of the wire while improving dimensional accuracy.

Construction Industry

In the construction field, surface-treated steel wire is widely used in structural parts such as steel mesh, guardrails and cable trays, and its anti-corrosion performance greatly extends its service life.

Automotive Industry

High-strength spring steel wire and brake wire used in automobile manufacturing need to have excellent wear resistance and fatigue resistance, and surface treatment production lines can provide them with a reliable protective layer.

Electronics and Communications

As conductor materials, the surface treatment of copper and aluminum wires directly affects the efficiency and stability of signal transmission. For example, tinned copper wire can effectively prevent oxidation and ensure long-term stable electrical performance.

Household Appliances

Wires, heating elements and connectors in household appliances usually need to be surface treated to meet safety standards and aesthetic requirements.

Aerospace and Military Industry

In high-end fields, the surface treatment of metal wires is particularly important. For example, titanium alloy wires can be used to manufacture lightweight and high-temperature resistant parts after anodizing.

Improving Product Performance

Surface treatment can significantly enhance the corrosion resistance, wear resistance and fatigue resistance of metal wires, thereby extending their service life.

Achieve versatility

Different surface treatment processes can customize the functions of wires according to customer needs, such as increasing conductivity, thermal insulation or decorative properties.

Improve production efficiency

Automated production lines reduce manual intervention, greatly improve processing speed and consistency, and reduce production costs.

Environmental protection and sustainability

Modern surface treatment technologies pay more and more attention to environmental protection, such as the use of chromium-free passivation agents and water-based coatings to reduce pollution to the environment.

With the advent of the era of Industry 4.0, metal wire surface treatment production lines are moving towards intelligence, greenness and efficiency:

Intelligent control

Introduce artificial intelligence and Internet of Things technologies to monitor the operation status of the production line in real time and automatically adjust parameters to optimize product quality and energy consumption.

Green and environmentally friendly process

Develop low-pollution and low-energy surface treatment technologies, such as nano-coating and laser treatment, to gradually replace traditional chemical processes.

New material adaptation

With the popularization of new alloys and composite materials, surface treatment production lines need to be continuously upgraded to adapt to a wider variety of substrates.

Multifunctional integration

Integrate multiple surface treatment processes into one production line to achieve one-stop processing and further improve flexibility and efficiency.

The metal wire surface treatment production line is not only an important part of modern industrial manufacturing, but also a key force in promoting the progress of materials science. It gives metal wires higher value and wider application prospects through advanced technologies and processes. In the future, with the continuous innovation of science and technology, this field will continue to break through traditional limitations, provide more high-performance and high-reliability solutions for all walks of life, and help the global manufacturing industry move towards a more intelligent and sustainable future.

EN

EN

English

English Español

Español Français

Français Português

Português عربى

عربى